JINGGONG Textile Machine – The leader of Textile Machinery in China

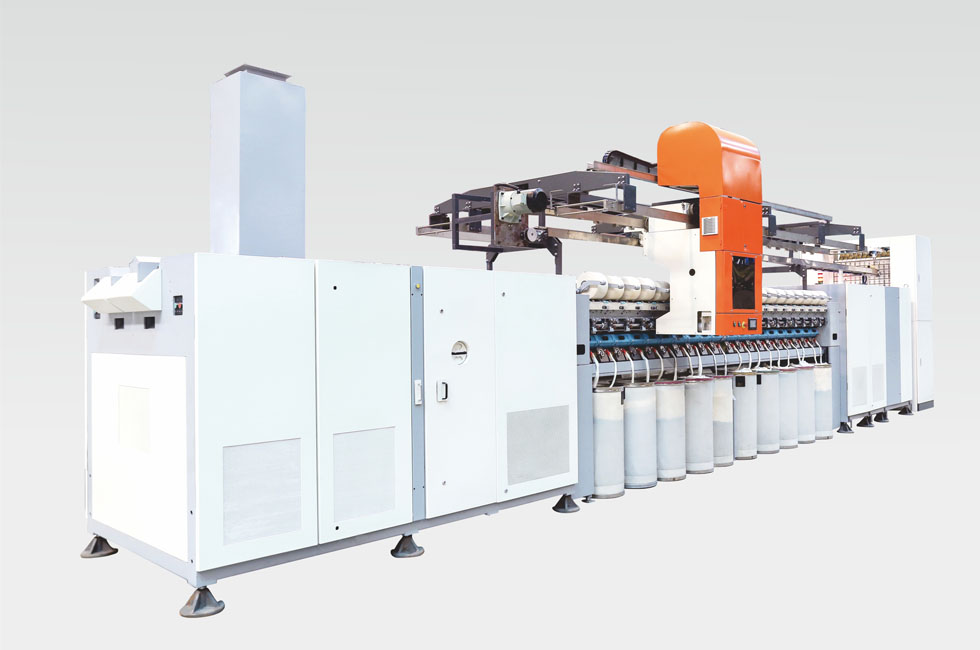

Texturing Machine

Texturing Machine mainly processes POY raw yarn (polyester pre-oriented yarn) into false-twist textured yarn (DTY polyester elastic yarn) with low elastic properties by stretching and false-twisting texturing. Different varieties of network yarn can be processed. DTY network filament: Network filament refers to the filament in which the filaments are entangled with each other and form periodic network points through the action of jet air flow in the network nozzle.

Rotor Spinning Machine

Yarn Covering Machine

Enterprise advantages

Product quality

High-standard and high-precision production tooling requirements, providing products that meet customer needs and whose quality can withstand international evaluations.

After-sale

The perfect after-sales service system has always insisted that the equipment installation is the responsibility of the company's personnel, the standards are unified, and the installation quality is tracked and assessed.

Research & development

Has a professional technology research and development center, high-end technology research and development talents, and cooperates with industry associations, domestic and foreign research and development institutions and colleges to innovate.

Energy saving

The application of more optimized systems and imported parts enables some models to save 10% energy compared with other brands of equipment with the same configuration.

Frequently Asked Questions

The main sales areas of our equipment are Southeast Asia, the Middle East and South America. Major countries such as: Indonesia, India, Pakistan, Turkey, Brazil, Egypt, etc.

Yes, we have a professional team to provide online and offline service installation support.

The warranty period for general equipment is 1 year.

As we insist on putting quality first and spend a lot of time and money developing how to make machines more automated, more productive, and less energy intensive.

Didn't find what you were after? Visit the Services Page