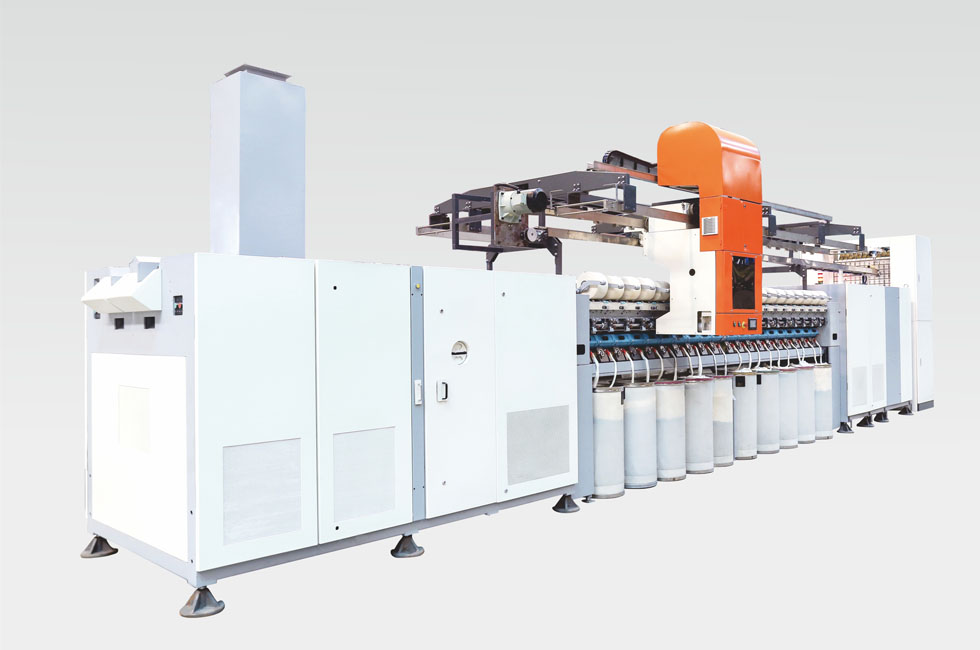

Rotor Spinning Machine, Open End Spinning Machine

Fibres are spun into yarn, and yarns are woven or knitted into fabrics, and fabrics are then transformed into clothing products. There are three popular techniques of yarn manufacturing like ring spinning, rotor or open-end spinning and air-jet spinning. Among them, ring spinning is the oldest and till now used to make a wide range of yarn counts. On the other hand rotor and air-jet spinning is modern spinning machines. These modern spinning machines are introduced overcoming the drawbacks of the ring spinning process.

Rotor Spinning, Open End Spinning

Rotor spinning (commonly called “Open End spinning”) is a process that incorporates spinning and winding operations. With the Open End system, the sliver coming from the draw frame is directly transformed into yarn, wound onto package cones. In the count range in which it can be used, the use of the rotor spinning machine allows an abbreviated production cycle and greater production per unit.

Open-end or Rotor spinning is one of the most modern techniques for spinning and winding. In this process, spinning and winding are sensibly combined in one process. This process goes beyond all ring Spinning problems by separating twisting and winding in the yarn manufacturing method. It has set itself alongside the ring frame. On the one hand, the progress of rotor spinning is due to a substantial productivity improvement and, on the other hand, to the possibility of full motorization of the spinning method. This is possible because it consolidates three manufacturing processes like Speed frame, Ring frame, and winding – into individual steps. It was not only the economic benefits but constant development in your parameter.